Every entrepreneur sourcing a new product faces a fundamental choice that will define their brand's future. You have two quotes in front of you: one from Supplier A is astonishingly cheap, promising high profit margins. The other, from Supplier B, is 20% more expensive but they emphasize their superior quality systems. Which do you choose?

This is the classic cost vs quality in manufacturing dilemma. For new brands, the lure of a lower price is incredibly powerful. But as any experienced procurement manager will tell you, the price on the quotation is rarely the true final cost. This guide will move beyond the simple "you get what you pay for" cliché. We will break down the long-term implications of each approach and provide a practical framework for choosing a supplier that aligns with your brand’s ultimate goals.

The Lure of "Lowest Cost": Short-Term Appeal and Long-Term Risks

The cost-first approach, often associated with low-cost country sourcing, is tempting for a reason. It offers a lower initial investment, which means less risk for a startup's first inventory run. It also allows for a lower retail price or a higher potential starting profit margin on paper. For brands competing in a price-sensitive market, this seems like the logical path.

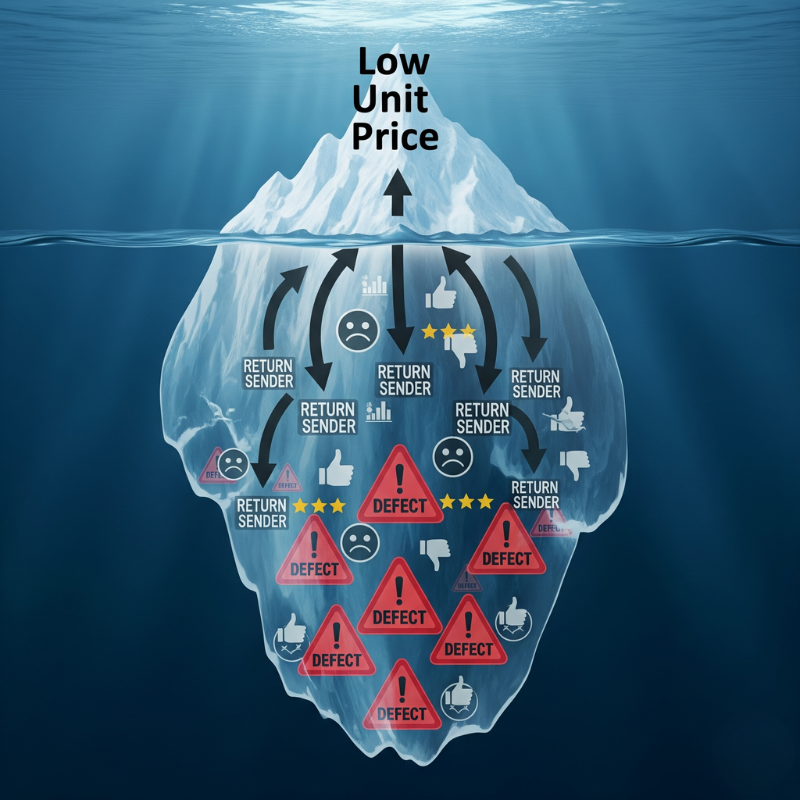

However, the initial factory price is just the beginning of the story. Prioritizing cost above all else often leads to significant hidden costs down the line. This is where the concept of Total Cost of Ownership (TCO) becomes critical. The "cheaper" supplier can end up being far more expensive due to:

- Higher Defect Rates: A low-cost factory may cut corners on materials or their quality control processes. This can lead to a higher percentage of unsellable products, which you have already paid for.

- Increased Customer Returns: Defective or poorly performing products lead to unhappy customers, negative reviews, and high return rates. The cost of return shipping, replacement inventory, and customer service time can quickly erase any initial savings.

- Damage to Brand Reputation: In the age of social media, a single bad batch of products can lead to a wave of negative reviews that can permanently damage a new brand's reputation. This is a cost that is hard to quantify but can be fatal.

- Wasted Management Time: You, the brand owner, will end up spending more of your valuable time dealing with quality problems, managing angry customers, and arranging inspections, instead of focusing on growing your business.

From our perspective in a hub of precision manufacturing, we have seen countless brands learn this lesson the hard way. The initial savings from a low-cost supplier are often completely wiped out by the long-term costs of poor quality.

The Power of "Best Quality": Investing in Your Brand's Future

Opting for high-quality manufacturing is not an expense; it's an upfront investment in your brand's future. While the Unit Price will undoubtedly be higher, the long-term payoffs create a more sustainable and profitable business.

- Higher Customer Satisfaction & Loyalty: A product that works perfectly, feels durable, and has a premium finish creates happy customers. Happy customers leave positive reviews, buy from you again, and tell their friends. This organic marketing is priceless.

- Lower Total Cost of Ownership (TCO): The math is simple. With fewer defects and lower return rates, the actual cost per sellable unit is often lower in the long run.

- Stronger Brand Positioning: A high-quality product allows you to confidently position your brand as a premium, reliable choice in the market. This justifies a higher retail price and protects you from having to compete in price wars at the bottom of the market.

- A True Long-Term Partnership: Quality-focused factories tend to be better long-term partners. They invest in their own technology and processes, are more collaborative in solving problems, and are aligned with your goal of building a great product.

A Practical Framework for Choosing a Supplier

So, how do you make a balanced decision? Don't just compare the price tags. Use a Supplier Scorecard to evaluate potential partners on a range of criteria. This is a tool to quantify your supplier evaluation criteria based on what is most important to your brand.

Here is a simplified example. You assign a "weighting" to each criterion based on your brand's priorities. A premium brand might give "Quality" a 40% weight, while a brand selling a disposable item might give "Price" a higher weight.

| Evaluation Criteria | Supplier A (Low Cost) | Supplier B (High Quality) | Weighting |

| Unit Price | $8.50 (Score: 10/10) | $10.00 (Score: 7/10) | 30% |

| Quality Management System (QMS) | No ISO 9001, basic QC (Score: 4/10) | ISO 9001 Certified, advanced testing (Score: 9/10) | 40% |

| Communication & Responsiveness | Slow, broken English (Score: 5/10) | Professional, fluent, fast (Score: 9/10) | 20% |

| Experience with Your Market | Limited (Score: 6/10) | Extensive, works with US brands (Score: 9/10) | 10% |

| WEIGHTED SCORE | 6.5 / 10 | 8.5 / 10 | 100% |

As the scorecard shows, even though Supplier A is cheaper, Supplier B is the clear winner when you factor in the critical elements that lead to a successful long-term business.

Conclusion: It's a Strategic Choice, Not a Price Tag

The cost vs quality in manufacturing debate is not about finding the cheapest factory. It's about finding the right factory for your specific Brand Positioning. A low-cost strategy can seem appealing but often carries hidden costs that can cripple a new brand. A quality-first strategy requires a higher upfront investment but builds a strong foundation for sustainable growth, customer loyalty, and a premium brand reputation.

In a world of endless manufacturing options, choosing a supplier is one of the most important decisions your brand will ever make. The most successful brands understand that true value is not measured by the price you pay for your first order, but by the quality and reliability you deliver to your customers for years to come.